Fixing an old tachometer

My local car shop owner asked me for a help. He was having a

problem with a non working tachometer used for a 93 Celica GT.

He has tried to replace the tachometer but it was totally

impossible to obtain any new or used one.

The car is 25 years old and the parts availability is now quite

low. But the car itself looks very new both inside and out.

The car was designed and made at the golden era of Toyota.

The engine runs well too and he really wanted to fix the

tachometer expecting me to do it.

He quickly removed the cluster unit from the dashboard and

showed it to me although he was busy doing another project

when I visited.

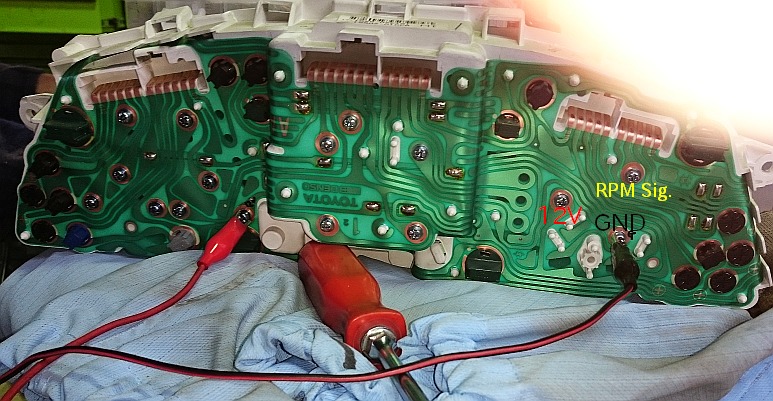

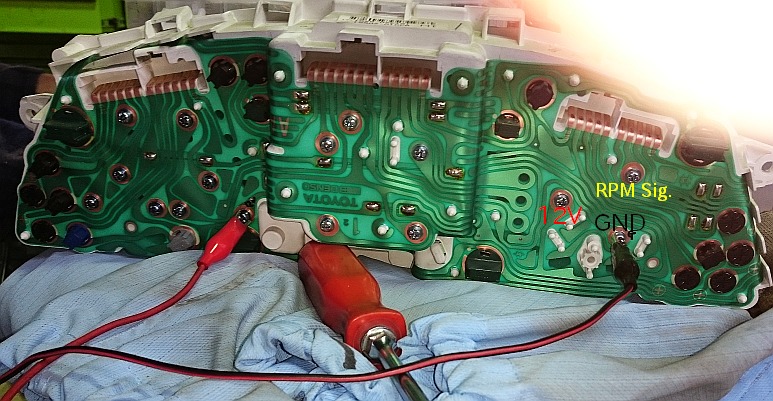

Below is the rear view of it. The tachometer is held by 3

screws as is shown. Those 3 are also used for the terminals

to supply +12V, to connect to the ground and the RPM in signal

judging from traces and other components surrounded.

So removing those 3 screws makes it possible to remove

the tachometer unit from the cluster and check it at a bench.

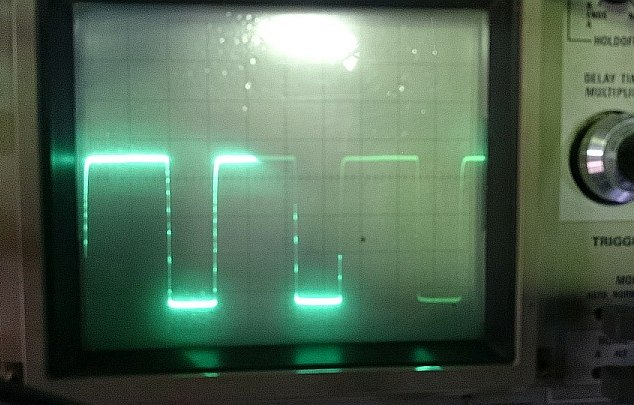

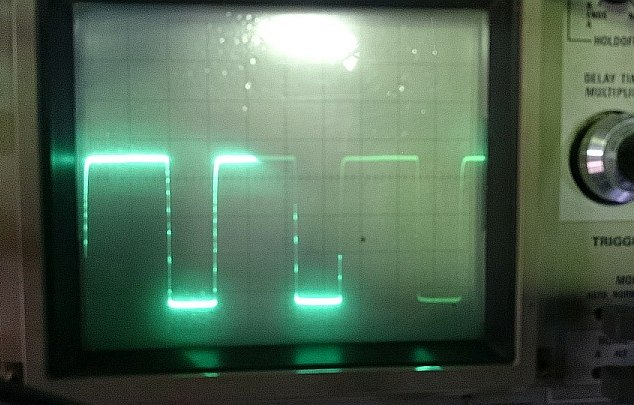

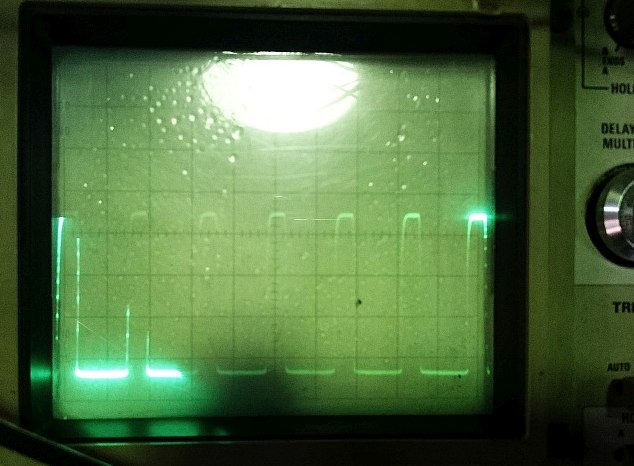

the 60Hz or 120Hz signals from a simple home made signal

generator. The reason why it is simple is that the signal

source is not generated inside but is getting the 60Hz energy

from the power company. It is consisting of a modified AC

adapter and a circuit to make square waves of 60Hz and

120Hz. A 60Hz square wave signal can drive the tachometer

to indicate 1800rpm and 120Hz, 3600rpm in case of a 4 cylinder

engine. Probably you may wonder why a power company's

60Hz can be used for the check of a tachometer. I will be

explaining it later.

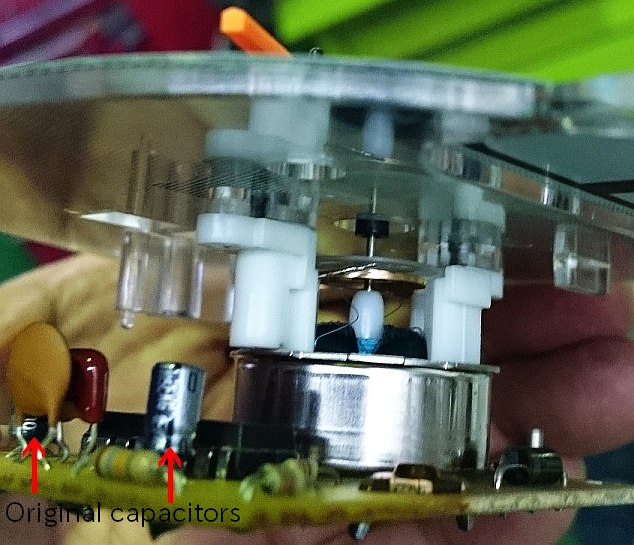

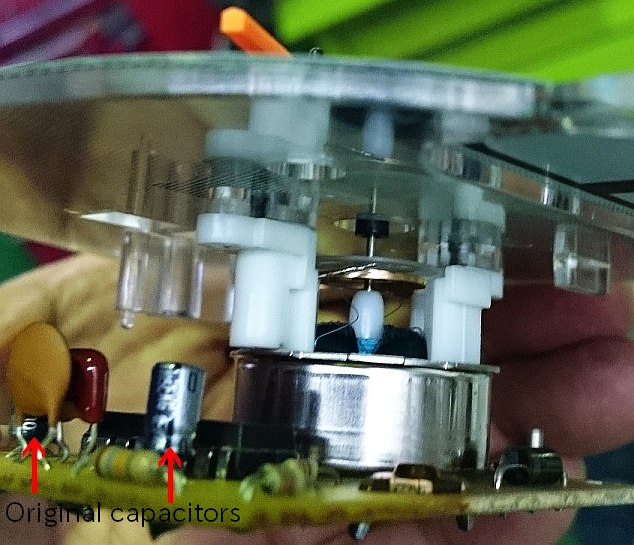

As I checked the board behind the tachometer panel, there

were 2 electrolytic capacitors 10uF/25V. Those 2 had a

symbol mark of Matsushita. These days I have been

experiencing problems caused by aged Matsushita's

electrolytic capacitors. They were commonly dried up

badly. Of course electrolytic capacitors will dry up some

day in accordance with the Arrhenius equation, but

Matsushita's ones dry up quicker than other major

Japanese brands due to the reason that the rubber

becomes more brittle than others according to my

experience. Actually, I recently had a door's lock/unlock

problem on a 18 years old Subaru Pleo and it was caused

by old Matsushita's electrolytic capacitors. With these

my own experience, I dare removed those 2 capacitors

and replaced with new ones manufactured by Nippon

Chemion. Speaking of electrolytic capacitors, QAS capacitors

fabricated by Nichicon also end the life quicker than others

and auto mobile industries had some impact. One example is

the Celsior / LS400's ECU witten here below by a friend of mine.

https://www.clublexus.com/forums/ls-1st-and-2nd-gen-1990-2000/656360-all-my-crazy-lexus-issues-solved-ecu-leaking-capacitor.html

We have to be careful for aged electrolytic capacitors especially

the one with the QAS liquid inside and some company's one with

a rubber which becomes very hard like a plastic and brittle as

are like those 2 used for a Celica's tachometer.

one showed more than 600ohms and the other infinity.

These were surely dead or almost so.

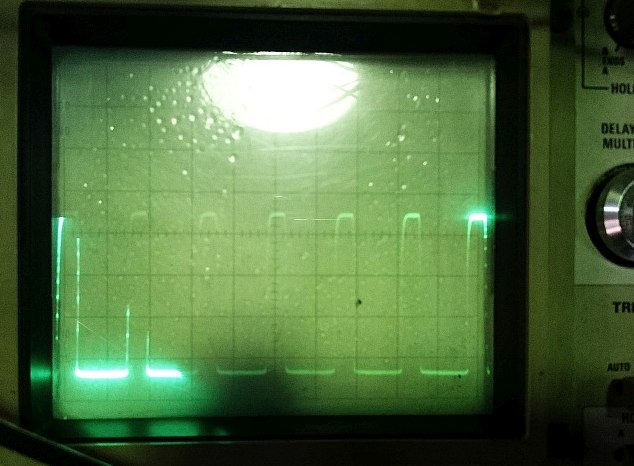

applying 60Hz and 120Hz attaching the signal generator.

After installing the cluster unit to the dashboard, the shop

owner said, “It's working perfectly. Thanks for the help and

I'll take you to a dinner appreciating your efforts”.

I am counting on what he'll serve me.

p { margin-bottom: 0.25cm; line-height: 120%; }p { margin-bottom: 0.25cm; line-height: 120%; }

problem with a non working tachometer used for a 93 Celica GT.

He has tried to replace the tachometer but it was totally

impossible to obtain any new or used one.

The car is 25 years old and the parts availability is now quite

low. But the car itself looks very new both inside and out.

The car was designed and made at the golden era of Toyota.

The engine runs well too and he really wanted to fix the

tachometer expecting me to do it.

He quickly removed the cluster unit from the dashboard and

showed it to me although he was busy doing another project

when I visited.

Below is the rear view of it. The tachometer is held by 3

screws as is shown. Those 3 are also used for the terminals

to supply +12V, to connect to the ground and the RPM in signal

judging from traces and other components surrounded.

So removing those 3 screws makes it possible to remove

the tachometer unit from the cluster and check it at a bench.

the 60Hz or 120Hz signals from a simple home made signal

generator. The reason why it is simple is that the signal

source is not generated inside but is getting the 60Hz energy

from the power company. It is consisting of a modified AC

adapter and a circuit to make square waves of 60Hz and

120Hz. A 60Hz square wave signal can drive the tachometer

to indicate 1800rpm and 120Hz, 3600rpm in case of a 4 cylinder

engine. Probably you may wonder why a power company's

60Hz can be used for the check of a tachometer. I will be

explaining it later.

As I checked the board behind the tachometer panel, there

were 2 electrolytic capacitors 10uF/25V. Those 2 had a

symbol mark of Matsushita. These days I have been

experiencing problems caused by aged Matsushita's

electrolytic capacitors. They were commonly dried up

badly. Of course electrolytic capacitors will dry up some

day in accordance with the Arrhenius equation, but

Matsushita's ones dry up quicker than other major

Japanese brands due to the reason that the rubber

becomes more brittle than others according to my

experience. Actually, I recently had a door's lock/unlock

problem on a 18 years old Subaru Pleo and it was caused

by old Matsushita's electrolytic capacitors. With these

my own experience, I dare removed those 2 capacitors

and replaced with new ones manufactured by Nippon

Chemion. Speaking of electrolytic capacitors, QAS capacitors

fabricated by Nichicon also end the life quicker than others

and auto mobile industries had some impact. One example is

the Celsior / LS400's ECU witten here below by a friend of mine.

https://www.clublexus.com/forums/ls-1st-and-2nd-gen-1990-2000/656360-all-my-crazy-lexus-issues-solved-ecu-leaking-capacitor.html

We have to be careful for aged electrolytic capacitors especially

the one with the QAS liquid inside and some company's one with

a rubber which becomes very hard like a plastic and brittle as

are like those 2 used for a Celica's tachometer.

one showed more than 600ohms and the other infinity.

These were surely dead or almost so.

applying 60Hz and 120Hz attaching the signal generator.

After installing the cluster unit to the dashboard, the shop

owner said, “It's working perfectly. Thanks for the help and

I'll take you to a dinner appreciating your efforts”.

I am counting on what he'll serve me.

Regarding the home made signal generator, originally

it was a AC adapter of a 6VDC. I added 2 rectifying

diodes inside to get the half-wave rectified waveform

and the full-wave rectified waveform. Using a Schmitt

it was a AC adapter of a 6VDC. I added 2 rectifying

diodes inside to get the half-wave rectified waveform

and the full-wave rectified waveform. Using a Schmitt

trigger circuit, those are converted to square waves of

60Hzand 120Hz. A 4cycles of 4 cylinders engine's

60Hzand 120Hz. A 4cycles of 4 cylinders engine's

revolution 1800rpm means 30rps and the engine ignites

2 times at each revolution. This means that there are

60 ignitions in 1 second. This is the reason why a power

company's 60Hz energy can drive the tachometer

1800rpm and the twice frequency 120Hz, 3600rpm.

This simple method is enough for us to check the

tachometer without buying an expensive signal

generator. This certainly is a poor man's method

but quite effective to check a tachometer as well

2 times at each revolution. This means that there are

60 ignitions in 1 second. This is the reason why a power

company's 60Hz energy can drive the tachometer

1800rpm and the twice frequency 120Hz, 3600rpm.

This simple method is enough for us to check the

tachometer without buying an expensive signal

generator. This certainly is a poor man's method

but quite effective to check a tachometer as well

as a speedometer since 60Hz drives the speedometer

85km/H and 120Hz, 170km/H.